How to Restore DWR for Waterproof Apparel

Outdoor apparel has evolved together with our pursuit for adventure. With every new advancement came the possibility of another realm of exploration – even harsher landscapes and more inhospitable environments became worlds left to explore. Some have been fortunate mistakes, and others have been intentionally designed; nevertheless, our enjoyment of the outdoors continues to be made better by these advancements, and DWR is certainly one of them.

What is DWR

DWR is short for Durable Water Repellent, and it’s the first line of defense against inclement weather, preventing the face fabric of your waterproof jacket and pants from becoming saturated.

Chemically speaking, DWR belongs to the abundant world of polymers – fluoropolymers to be exact. These polymers are characterized by carbon-fluorine bonds, which exhibit a high resistance to solvents, acids and bases, such as water. If high school chemistry has been completely wiped from your memory, then remember that a polymer is just a large molecule, composed of many repeated sub-units. Technically, the longer the chain of sub-units, the more effective the DWR is at keeping moisture on the surface of your jacket.

How Does Durable Water Repellent Work

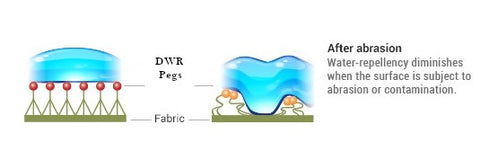

In order to understand how DWR works, it helps to visualize the characteristics of the substance. Once the liquid solution is applied to your outdoor apparel, DWR creates microscopic pegs or small filaments that protrude from the face fabric. These small pegs decrease the amount of possible surface area each molecule of water can inhabit. Without a large enough surface to cling to, DWR forces water molecules to “ bead up”, effectively increasing the water’s surface tension such that what would be a puddle is now a ball of water - rolling off the garment effortlessly, and not soaking through.

How to Apply DWR to Waterproof Jacket and Pants

There is a common misconception that waterproof jackets and waterproof pants should not be washed very often. However, the fact of the matter is, your jacket and pants need to be washed and subsequently retreated with DWR to ensure continued performance. As mentioned before, the frequency with which you wash and reapply will depend on your usage of the garment, so make sure you’re testing your gear before you get out there!

It’s important to note that with every reapplication of DWR, it’s also necessary to wash the garment to ensure you remove unwanted substances that affect breathability and the effectiveness of the new DWR.

Unlike normal laundry detergents, waterproof apparel detergents are specially designed for waterproof jackets and waterproof pants. We highly recommend not using normal laundry detergents while cleaning waterproof apparel as these detergents can leave unwanted residue, such as perfumes, conditioners, bleaches, softeners, or other waxes or oils.

There are a wide range of products available for washing waterproof apparel, though we recommend Granger Performance Wash, for its Bluesign® approved, PFC-free properties.

Once you are done washing your waterproof apparel, it’s time to apply a fresh coat of DWR. We recommend using a spray-on application as opposed to a wash-in application. DWR is designed for the face fabric of your waterproof apparel. When you use wash-in DWR, you are applying a DWR to the interior of your jacket. Introducing DWR to the interior of your jacket effectively reduces the breathability and performance; hence, we highly recommend using a spray-on application like Grangers Performance Plus Spray.

Please Note: If you are using a different type of spray-on DWR, it might be necessary to heat treat the jacket after applying a new DWR finish. The introduction of heat to DWR activates those tiny pegs such that they stand straight up. If you are using a DWR that requires heat treatment, then these instructions should be denoted on the bottle.

- Spray directly onto a freshly-laundered, damp garment from roughly 10-15cm / 4-6’’ away

- Let sit for around 5 minutes

- Wipe away any large droplets with a clean towel

- Allow to dry naturally, or if tumble drying, always check the garment’s care label first. Showers Pass jackets can be dried at low temperatures.

Long Chain vs. Short Chain DWR: Environmental Concerns

Historically, most DWRs have been Perfluorinated Chemicals (PFCs). These chemicals are composed of long chains of carbon atoms to which fluorine atoms are bonded. Longer chains tend to make for more effective DWRs, but they also have toxic byproducts that can accumulate in nature. Perfluorooctanoic acid (PFOA), also known as C8, was the standard DWR for outdoor gear for many years. As the name implies, this chemical had a chain of 8 carbon atoms. While exposure to these chemicals from one’s apparel wasn’t a health risk, the effects to communities surrounding its production and the use of such chemicals in food packaging was highly problematic. As a result, C8 chemicals are no longer used. After C8 was phased out, the same job is now done with similar molecules with shorter chains of atoms that break down more quickly. “Short Chain” or “C6” DWR replaced C8 as the industry standard.

These chemicals are still seen as a necessary evil to an extent. The future will likely trend towards PFC free DWRs. These compounds are improving every year, but the unique chemical characteristics of fluorinated chemicals still makes them the most effective at shedding water, as well as requiring less frequent reapplication. While a PFC free DWR may seem like a no-brainer from the standpoint of sustainability and environmental stewardship, it can actually be a complicated decision point for sustainably minded apparel brands. When considering the environmental footprint of a garment, it’s important to consider the whole life of the garment, not just production. Increasing the usable life of a garment has long been considered one of the most effective ways to decrease its environmental impact. Using a less durable or effective DWR at production means that the end user will need to wash and re-treat their garment more often. Apparel designers and developers need to carefully weigh the social and environmental impact of the additional use of water and electricity (both in washing and production of the aftermarket DWR) against the social and environmental effects of using PFCs. The results may vary from product to product depending on intended use, price point and customer expectations.

At Showers Pass, it’s our preference to use PFC free DWR whenever possible. That's why we choose to sell only Bluesign® approved PFC free care products on our website.

When to Replace Your DWR

“Wetting out” can be a good indication that your DWR requires revitalizing. The common causes of DWR degradation are exposure to dirt, body oils and grease in general, washing, sunscreen, smoke, bug spray, and normal abrasion sustained with regular use. Those small pegs of DWR defense have been compromised in one way or another. Either those small hairs have been knocked down, eliminated, or the space between them has become clogged, allowing cold temperatures and moisture to seep through to the membrane. A jacket that wets out may not let water in, but it can be cold, heavy and uncomfortable to wear. In some conditions, wetting out will create a temperature differential that can cause condensation to accumulate inside the garment.

You might be asking yourself: What’s the point? I have a waterproof membrane for that! Of course the assumption here is that a waterproof membrane is impermeable – no water in, and no water out! Though not entirely inaccurate, waterproof membranes are also micro-porous. The ability to allow body heat to escape from within is a quality of a good waterproof jacket, and something of which every consumer should be aware.

Long exposure to heavy rains and cold temperatures will push your gear to the limits. That’s why it’s important to ensure that your waterproof cycling jacket and waterproof pants remain protected by multiple DWR applications.

How Long Between Applications?

There’s no standardized time frame in which one should reapply a DWR defense. Of course everyone’s situation will be different given how often and how rigorously one uses their waterproof apparel. As mentioned in the above section, “wetting out” is the most obvious indication that it’s time to reapply a layer of DWR. However, if you are noticing a “clammy” feeling, which is to say the lining of your waterproof jacket feels moist and begins to cling to your skin, then this is also a good indication that a new layer of DWR should be applied.

How to Test Your DWR

Test your waterproof apparel’s DWR by applying some drops of water to the face fabric. Wait a few minutes to see if those droplets of water remain balled up on the surface. If, however, you notice that the water sits flat against the garment and the area becomes slightly darkened, this is an indication that water is permeating the face fabric and it’s time to reapply.

And that’s it! Your waterproof jacket or Waterproof pants have been given new life. Allowing you to explore the outdoors with all the protection you need to stay dry, warm and happy.

If you have any questions, feel free to contact Showers Pass for details on best practices, or if you have any general questions about DWR.